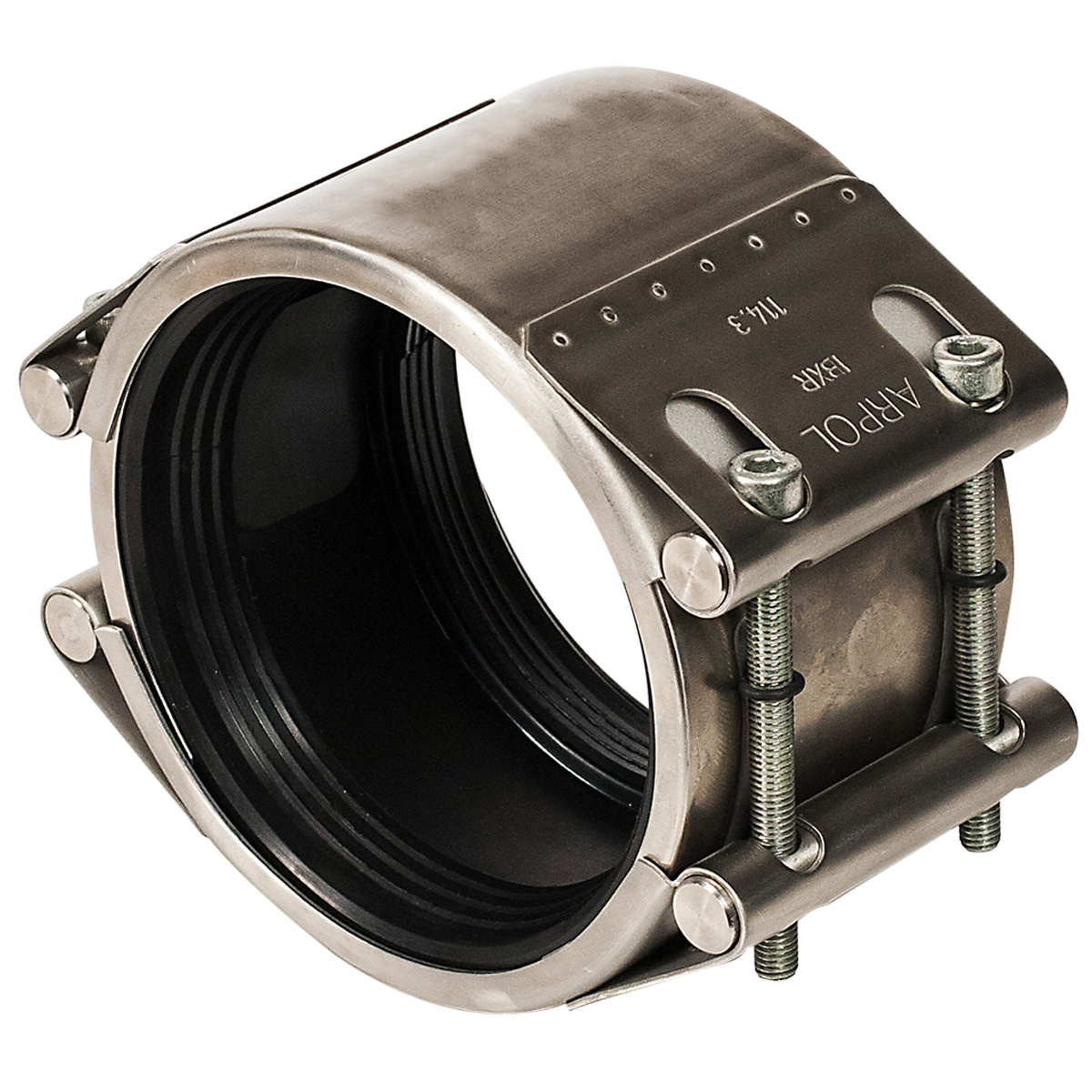

STYLE SS1

All stainless steel repair clamp - Normal Range .40”

Manufactured in the USA.

USE Full circumferential repair of splits and holes.

SIZES 2” - 12”

COMPATIBILITY Steel, cast iron, asbestos cement, plastic, other types of pipe.

WORKING PRESSURE Up to 150 psi.

NSF61 certified upon request.

MATERIALS

SHELL 304 Stainless Steel, 16 to 22 gauge depending on size.

SIDEBARS Heavy gauge 304 Stainless Steel, GTAW welded to form permanent fusion with shell.

LUGS 304 Stainless Steel, fused to sidebars by GMAW welding.

BOLTS 304 Stainless Steel, 4 inch clamps and smaller use 1/2" UNC rolled thread, 6 inch clamps and larger use 5/8" UNC rolled thread. Bolts are GMAW welded to sidebar.

NUTS Heavy hex, 304 Stainless Steel, 4 inch clamps and smaller uses 1/2" UNC threads, 6 inch clamps and larger uses 5/8" UNC thread. Nuts coated to prevent galling.

WASHERS 5/8" 304 Stainless Steel flat washers. SS1's 13.55 and larger, SS2's 13.50 and larger and all SS3's receive Stainless Steel flat washer. 1/2" or 5/8" Plastic washer prevents galling between nut or stainless steel washer and lifter bar, on all sizes.

ARMORS Heavy gauge 304 Stainless Steel, bonded to gasket to bridge gap at lug area.

LIFTER BARS 304 Stainless Steel, lip curved to hold position while tightening. Heavy gauge serves as bearing surface for nuts.

GASKETS Virgin SBR rubber compounded for water and sewer service in accordance with ASTM D 2000 MAA 610. Other compounds available for petroleum or high temperature service, or other special applications.

Related Products

All-stainless steel two section repair clamp

Single section cast lug repair clamp

Stainless steel repair clamp that can also be used as a coupling