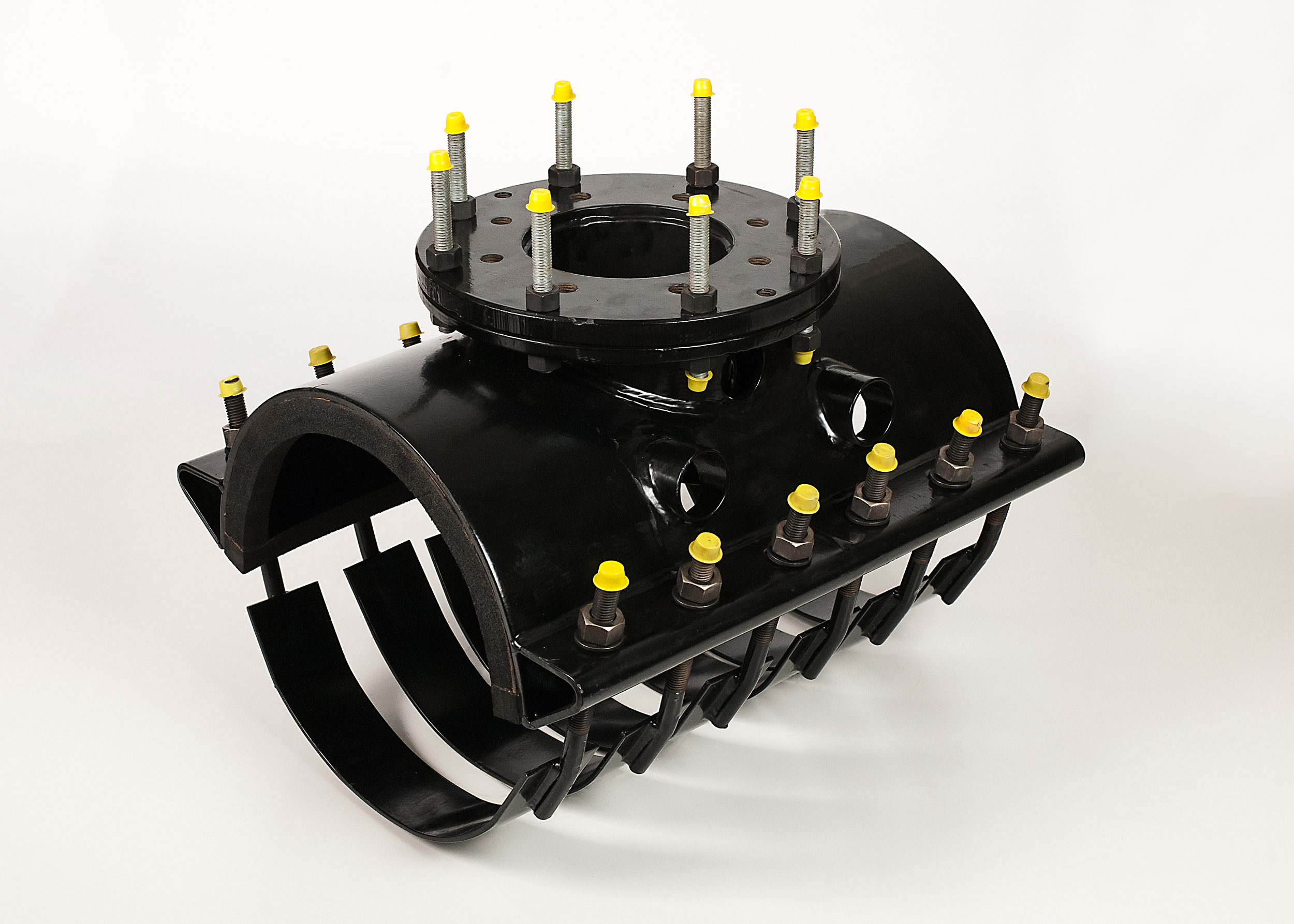

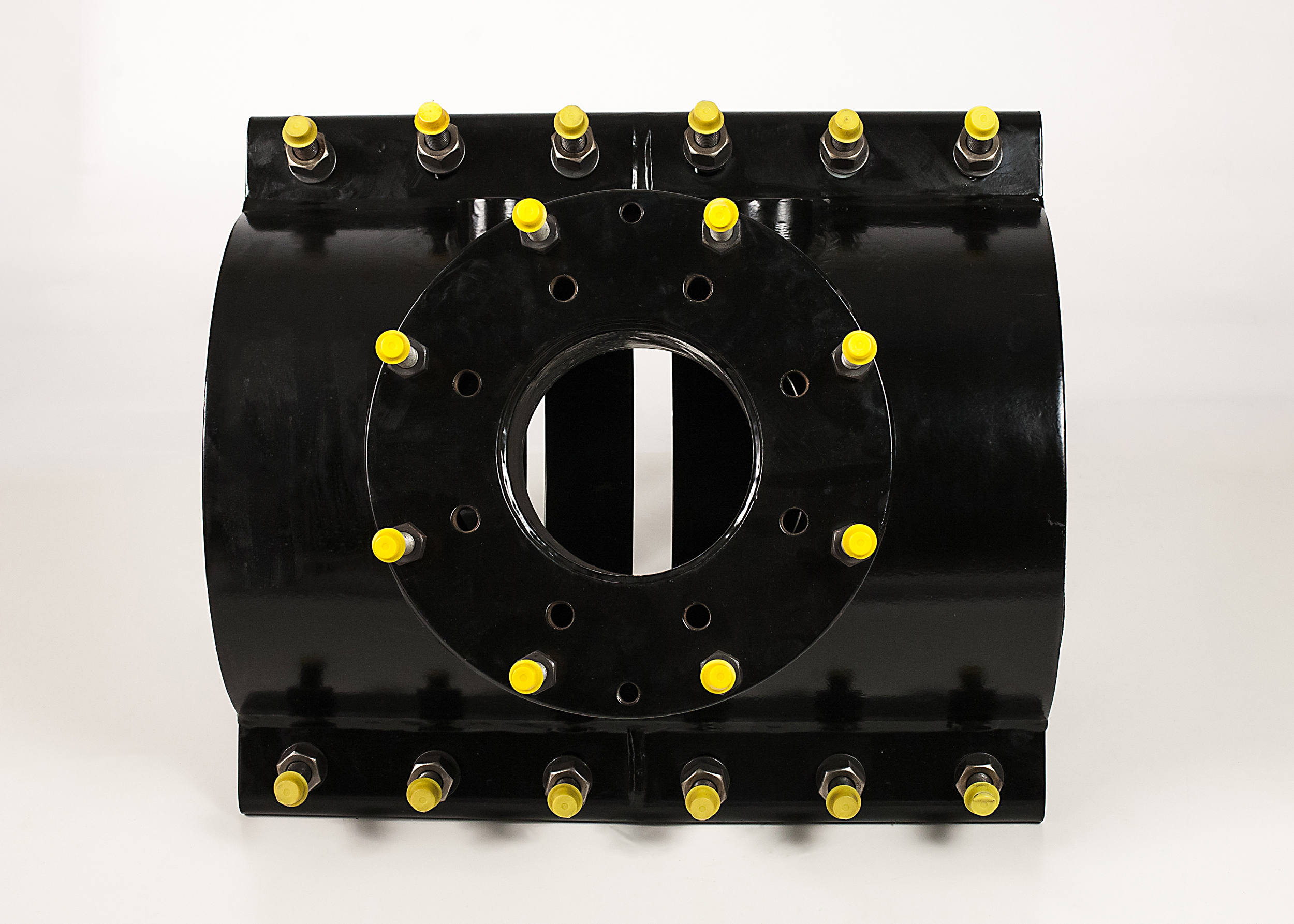

style FTS435

Fabricated steel tapping sleeve. Meets AWWA C223 & Manual M-9.

Manufactured in the USA.

USE To make a branch outlet.

SIZES Available for all sizes of concrete cylinder pipe.

OUTLET SIZES Determined by application.

COMPATIBILITY Concrete steel cylinder pipe.

WORKING PRESSURE See submittal.

NSF61 certified on request.

MATERIALS

BODY ASTM A 36 Steel Plate. Thickness and length along pipe determined by application pressure and size.

FLANGE Steel Ring Flange, compatible with ANSI Class 125 and 150 bolt circles, are standard. Counterbored to fit tapping valve lip per MSS SP-60 where applicable. Other flange styles are available. Information about make of valve and size of cutter necessary for flanges 14" and larger.

STRAP ASSEMBLIES High strength low alloy steel studs and nuts, meeting AWWA Standard C111. Straps are of ASTM A 36 steel. Type 304 and 316 Stainless Steel stud, nut and strap material optional.

NECK GASKET Gaskets are made from Styrene Butadiene Rubber (SBR) Compounded for water and sewer service in accordance with ASTM D 2000 3 BA715. Other compounds available for petroleum, chemical, or high temperature service.

GROUT SEAL One inch square high density Neoprene foam. 1/2" hard rubber stops provided to maintain minimum space between body of tapping sleeve and O.D. of pipe.

COATINGS Shop coat applied to parts for corrosion protection in transit. Coating of product with fusion bonded epoxy in accordance with AWWA C213 is optional.