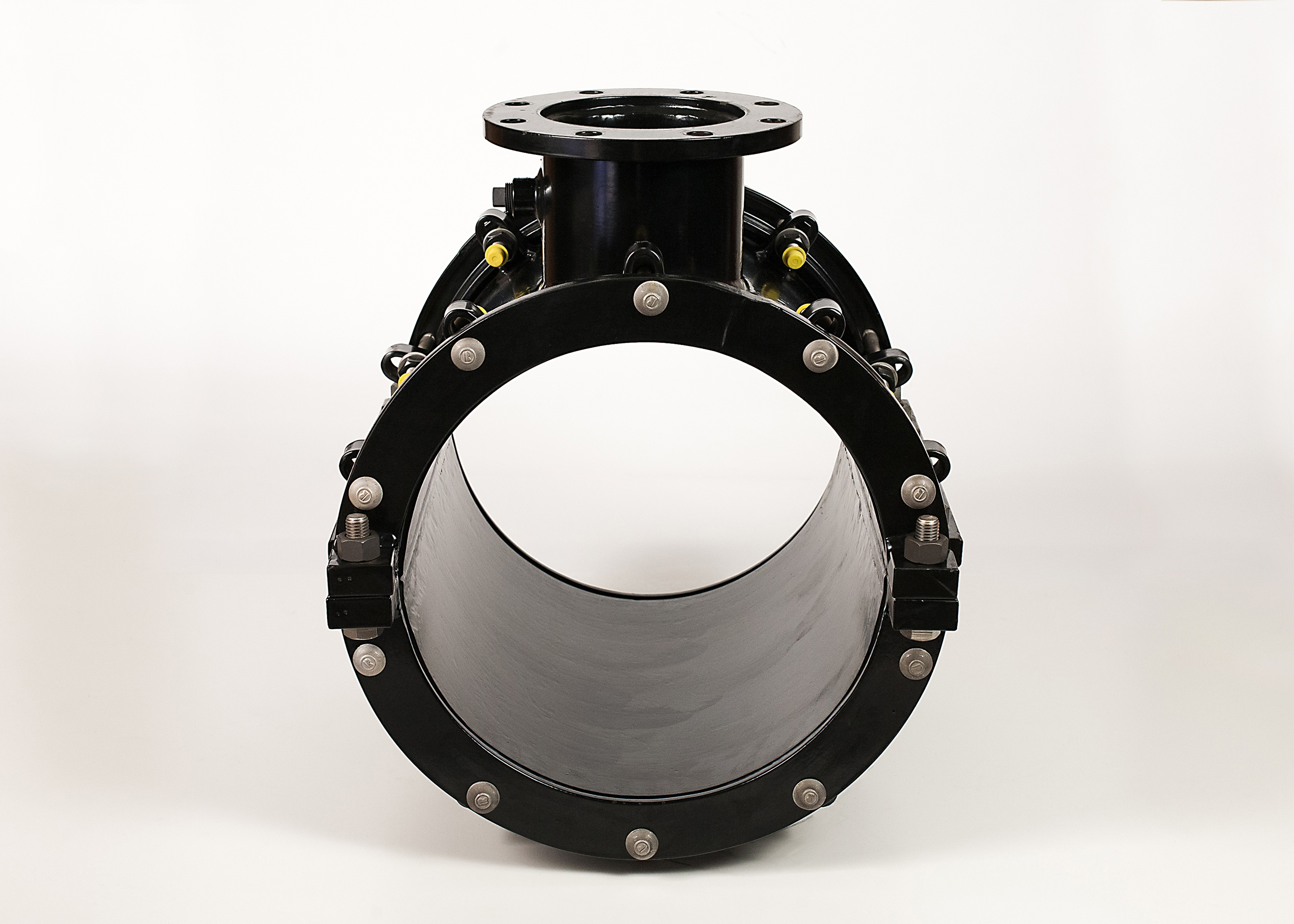

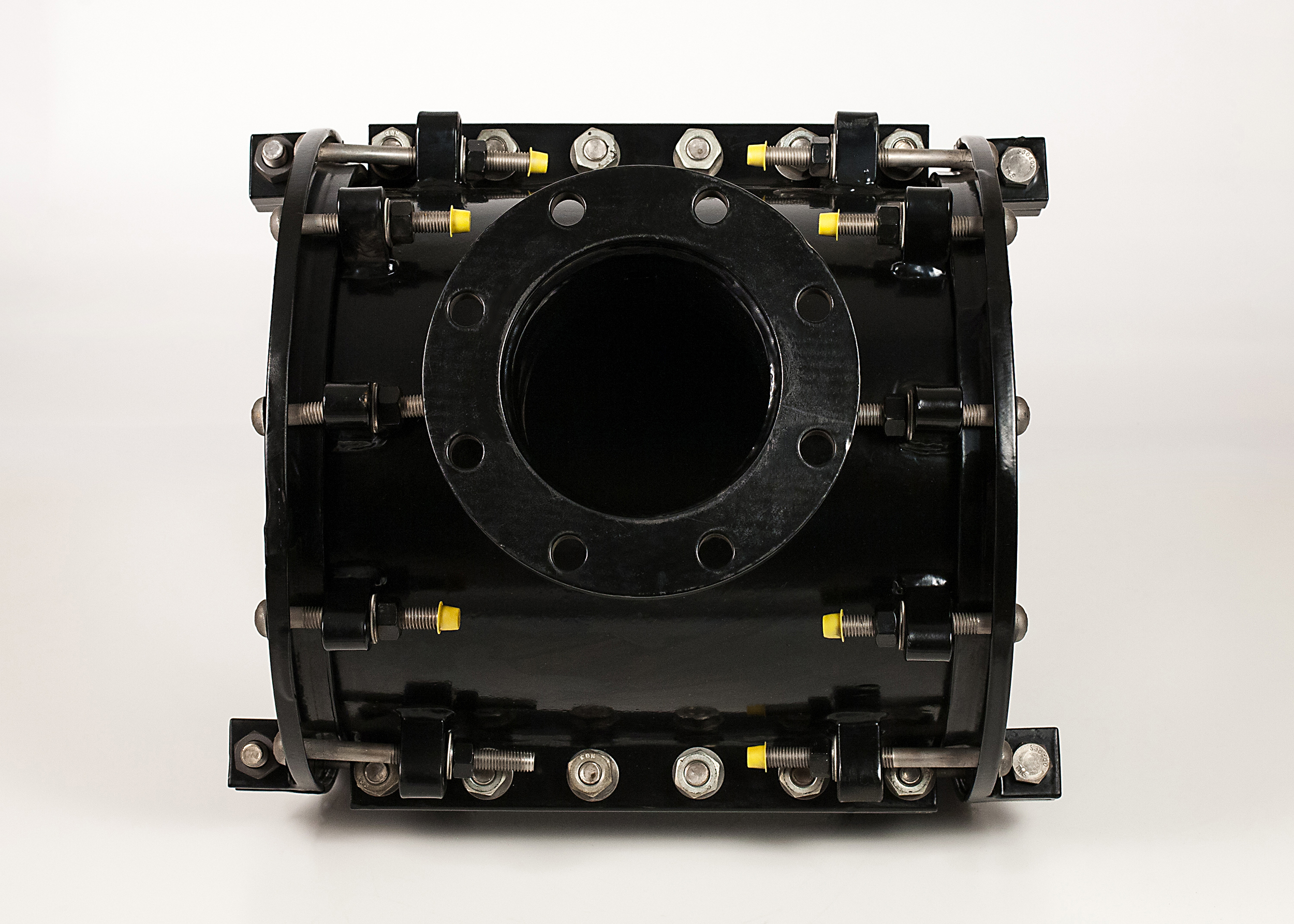

style FTS425

Fabricated steel tapping sleeve with side and end gasket seals. Meets requirements of MSS SP-124 and AWWA C223.

Manufactured in the USA.

USE To make a branch outlet from a main supply line with extra protection for lines subjected to excessive beam loads.

SIZES 12" - 96"

OUTLET SIZES 4" - 96"

COMPATIBILITY Steel, cast iron, asbestos cement, plastic and other types of pipe.

WORKING PRESSURE See submittal.

NSF61 certified on request.

MATERIALS

BODY ASTM A36 Steel Plate.

END RINGS Mill rolled ASTM A 36 Steel Bar.

FLANGE AWWA Class D Steel Ring Flanges, compatible with ANSI Class 125 and 150 bolt circles, are standard. Counterbored to fit tapping valve lip per MSS SP-60. Other flange styles are available.

BOLTS AND NUTS High strength low alloy steel bolts and nuts. Steel meets AWWA Standard C111. Type 304 and 316 Stainless Steel bolt material optional.

GASKETS Gaskets are made from Styrene Butadiene Rubber (SBR) compounded for water and sewer service in accordance with ASTM D 2000 3 BA715. Other compound available for petroleum, chemical, or high temperature service.

COATINGS Shop coat applied to parts for corrosion protection in transit. Fusion bonded epoxy, liquid epoxy and other coatings available on request.